COOLING TOWER DT

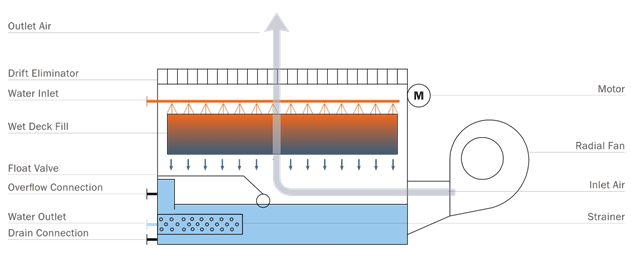

The DT cooling tower is used where chillers require large quantities of water. In industry the cooling water from air compressors, diesel engines and generators can be re-cooled and recirculated. The use of a cooling towers for re-cooling water is based on the high evaporation temperature of water. By using a heat ex-changer, up to 98% of water can be saved.

The application of a cooling tower for water re-cooling is based on the high vaporization (latent) heat of water. Through the application of a re-cooling unit some appreciable water saving of up to 98% can be achieved. Space-saving design, easy assembly easy maintenance and operations plus an extensive array of accessories make the DT cooling tower an unbeatable choice.

Requirements:

- no high demand on the quality of the cooling water

- initial costs more important than maintenance costs

- low cooling water temperatures (approx. 5K above wet-bulb temperature)

Areas of use:

- in the open

- on top floors

- in rooms with high ceilings

Your benefit:

- uncomplicated system / easy maintenance

- small dimensions / space-saving design

- low noise level

- low weight

- low consumption of electricity

- low investment costs

- simple installation

- extensive range of accessories

COOLING TOWER DT XL

With the Cooling Tower DT XL GOHL-HEGER has designed a Tower with a higher cooling capacity (15% more) with the same floor space requirements.this is great when there is limited space to place the coolers.

SIDE-STREAM COOLING TOWERS SK

The side-stream cooling tower is used where large amounts of water are required for refrigeration machines (same as vapor tower), but where the installation conditions, for reasons of space, only allow a lateral connection of the air duct system, i.e. in the mezzanine, basement or rooms with low ceilings.

Horizontal ducting, exhaust air deflectors are integrated in the device – no incidence of debris entering the cooler from above