LONG TERM CORROSION PROTECTION WITH WHIRL SINTERING

Our cooling towers are manufactured based on state of the art design & technologies.

Our core competence is the so-called Whirl Sintering, a process we developed and refined over the last 40 years.

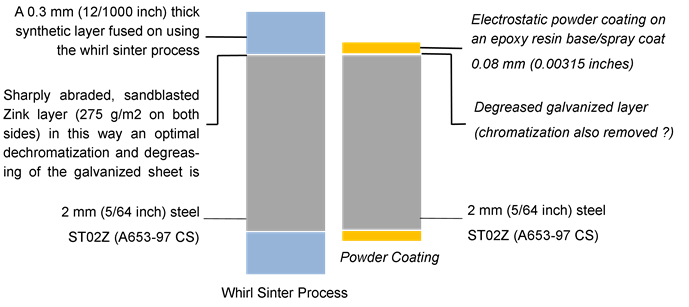

WHIRL SINTERING a 0.3 mm thick thermoplastic performance polymer alloy is melted onto clean, degreased and pretreated (sandblasted), Sendzimier Galvanized steel-sheet or profile in a powder whirl bed.

Sendzimir process (Tadeusz Sendzimir) is used to galvanize a steel strip by using a small amount of aluminum in the zinc bath and producing a coating with essentially no iron-zinc alloy. The process guarantees high resistance and durability characteristics.

The shiny, nonporous surface is highly impact resistant yet elastic; it is resistant to mild acids & bases, has a good UV and all weather resistance. The Whirl Sintered Surface Coating does not only prevent corrosion it also prevents deposit formation and macrofouling.

All of our galvanized sheet metal parts for cooling towers are Whirl Sintered to prevent corrosion.

Whirl Sintering has a couple of additional advantages:

- reduction in risk of injury(no sharp, rusty edges)

- improved sound insulation and reduced vibration

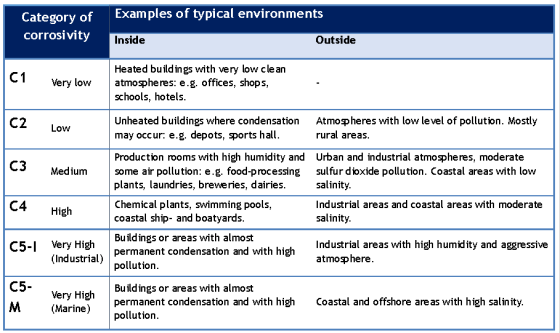

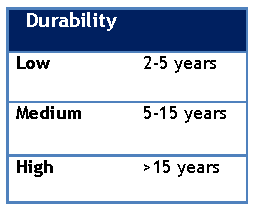

Whirl Sintered Cooling Towers are very corrosion resistant and durable. They have the highest corrosion class – C5-M very strong (sea). Regardless of where they are installed and used GOHL-HEGER will give you a product with a < 15 Years life expectancy “by design”.

substantially thicker coating compared to standard industrial procedure (3.7 x thicker)